-

Home

- About Us

- Products

-

LANGUAGE

Classify- Shot Blasting Machine

- Blast Machine Spares

- Maintenance & Retrofit

- Industrial Dust Collector

Shot Blasting Machine

Rail Through-Type Shot Blasting Machine

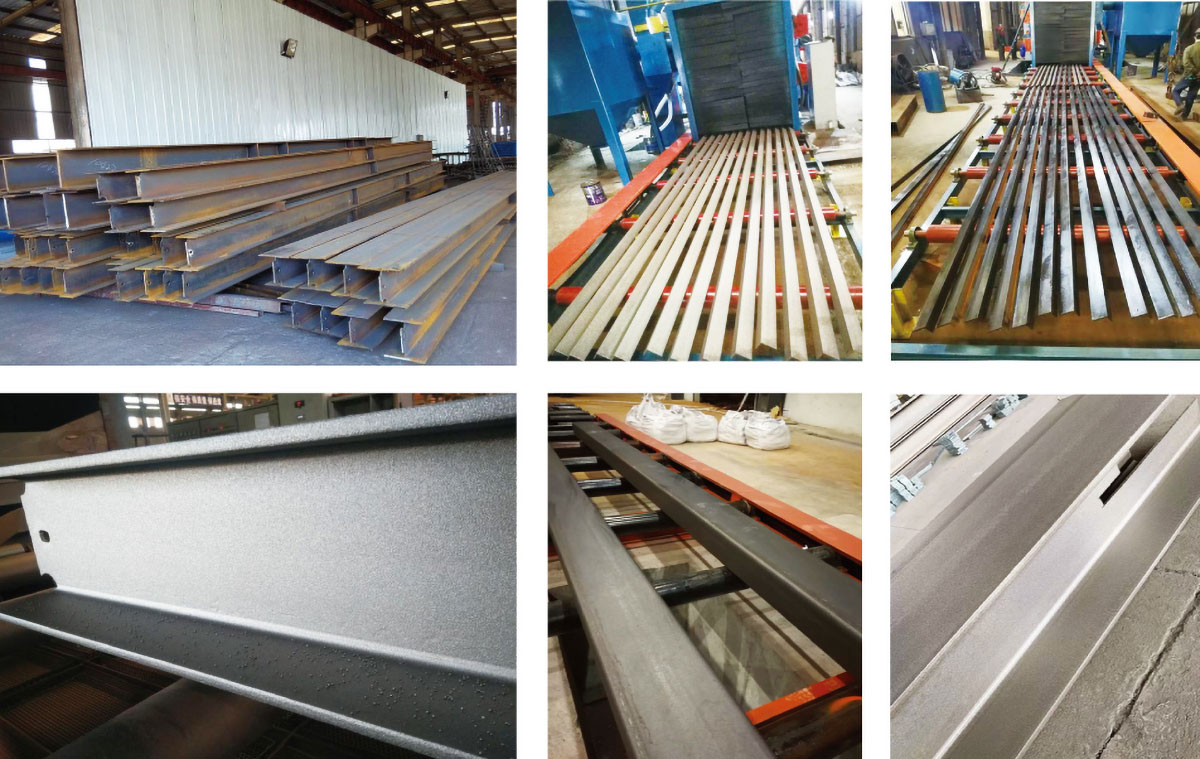

The roller through shot blasting machine can work continuously without interruption for various types of steel materials, such as steel plates, steel bars, steel beams, and steel sections,Steel pipes and cast steel parts are subjected to deoxidation, cleaning, and pretreatment in a continuous manner.

Rail Through-Type Shot Blasting Machine

The roller through shot blasting machine can work continuously without interruption for various types of steel materials, such as steel plates, steel bars, steel beams, and steel sections,Steel pipes and cast steel parts are subjected to deoxidation, cleaning, and pretreatment in a continuous manner. During the cleaning process, it is possible to The speed controlled conveyor roller feeds steel structural components or steel into the ejection area inside the cleaning machine room, and its various surfaces are subjected to different forces The strong and dense projectile impact and friction in the coordinate direction cause the oxide scale, rust layer, and dirt on it to quickly fall off The surface of the material will obtain a smooth surface with a certain roughness, and the workpieces can be loaded and unloaded on the inlet and outlet rollers outside the cleaning room. Falling into steel The pellets and rust dust on the material are blown by a blowing device, and the separated pure pellets are used for shot blasting cycle. Shot blasting cleaning Dust is generated and sent to the dust removal system through the exhaust duct. The purified air is discharged into the atmosphere.

Technical Parameter

Equipment model RDH0816 RDH1018 RDH1218 RDH1520 Door opening size mm (width x height) 800x1600 1000x1800 1200x1800 1500x2000 Number of shot blasting machines (power) 8 PCS x11kw 8 PCS x11kw 8 PCS x11kw 8 PCS x15kw Equipment model RDH2020 RDH2025 RDH2530 RDH3035 Door opening size mm (width x height)) 2000x2000 2000x2500 2000x3000 2000x3500 Number of shot blasting machines (power) 8 PCS x15kw 12 PCS x15kw 16 PCS x15kw 16 PCS x18.5kw

Comparison diagram of some products before and after shot blasting Copyright @ 2025 . All Rights Reserved Weifang Rongheng Machinery Co., Ltd.

Copyright @ 2025 . All Rights Reserved Weifang Rongheng Machinery Co., Ltd. - About Us